Oncalla is an American call center service provider. We provide Answering Services services. Hire our 24/7 Inbound customer service for your all American customers.

https://www.oncalla.com/s-answering-services.html

1

2

3

4

5

6

7

8

9

10

11

12

| <!--file: app/code/local/Atwix/ExtendedGrid/etc/config.xml--><adminhtml> ... <layout> <updates> <atwix_extendedgrid> <file>atwix/extendedgrid.xml</file> </atwix_extendedgrid> </updates> </layout> ...</adminhtml> |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

| <!--file: app/code/local/Atwix/ExtendedGrid/etc/config.xml--><adminhtml> ... <events> <sales_order_grid_collection_load_before> <observers> <atwix_extendedgrid> <model>atwix_extendedgrid/observer</model> <method>salesOrderGridCollectionLoadBefore</method> </atwix_extendedgrid> </observers> </sales_order_grid_collection_load_before> </events> ...</adminhtml> |

1

2

3

4

5

6

7

8

9

10

11

| /*file: app/code/local/Atwix/ExtendedGrid/Model/Observer.php*/ /** * Joins extra tables for adding custom columns to Mage_Adminhtml_Block_Sales_Order_Grid * @param $observer */ public function salesOrderGridCollectionLoadBefore($observer) { $collection = $observer->getOrderGridCollection(); $select = $collection->getSelect(); $select->joinLeft(array('payment'=>$collection->getTable('sales/order_payment')), 'payment.parent_id=main_table.entity_id',array('payment_method'=>'method')); } |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

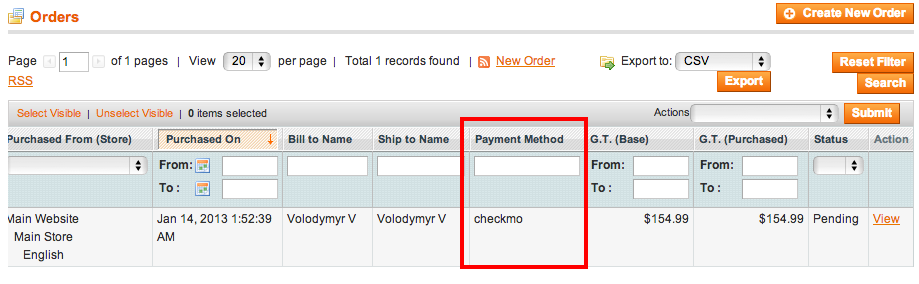

| <!--file: app/design/adminhtml/default/default/layout/atwix/extendedgrid.xml --><layout> <sales_order_grid_update_handle> <reference name="sales_order.grid"> <action method="addColumnAfter"> <columnId>payment_method</columnId> <arguments> <header>Payment Method</header> <index>payment_method</index> <filter_index>payment.method</filter_index> <type>text</type> </arguments> <after>shipping_name</after> </action> </reference> </sales_order_grid_update_handle> <adminhtml_sales_order_grid> <!-- apply layout handle defined above --> <update handle="sales_order_grid_update_handle" /> </adminhtml_sales_order_grid> <adminhtml_sales_order_index> <!-- apply layout handle defined above --> <update handle="sales_order_grid_update_handle" /> </adminhtml_sales_order_index></layout> |